Hey @littlepumpkin, I’m somewhat familiar with the coordinate systems but I use Fusion 360 and don’t have any experience with your software - so you’ll have to try and join the dots as best you can…

I’ll say a few words about rotated coordinate systems and then I’ll get on to your issue, just to make sure the ground work is covered.

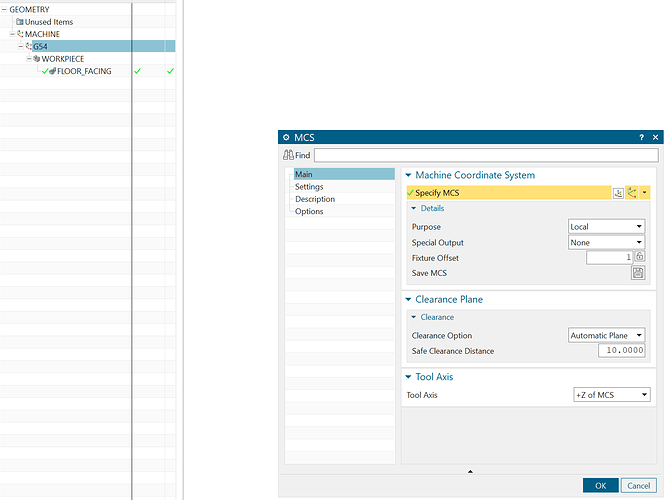

[In Fusion 360] When creating a Setup, the WCS can be chosen by the user as G54, G55, G56, etc. When posting the tool paths, under the multi-axis section, the default dumping ground for the rotated coordinate SYSTEM (RCS) is G59.3 (Fusion 360 default - you’ll see why in a bit). Imagine that your program has a load of different tool paths with the A & B tables at all different angles, each time they rotate for the next operation, the trigonometric relations for any WCS offsets are dumped into G59.3, so G59.3 gets overwritten over and over again. For this reason, Fusion won’t let the user choose G59.3 as a WCS if its also the RCS. Assuming all this makes sense, then let’s move on.

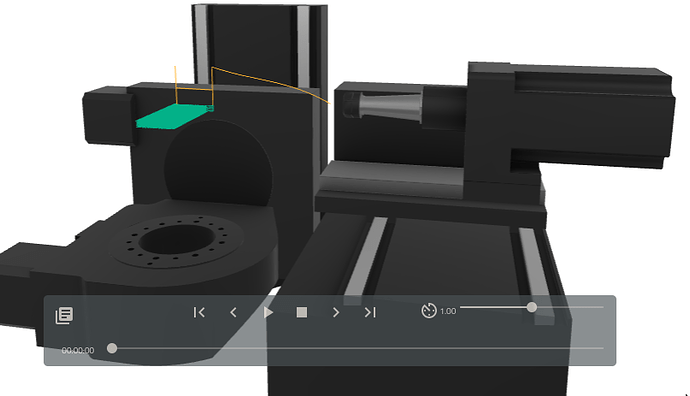

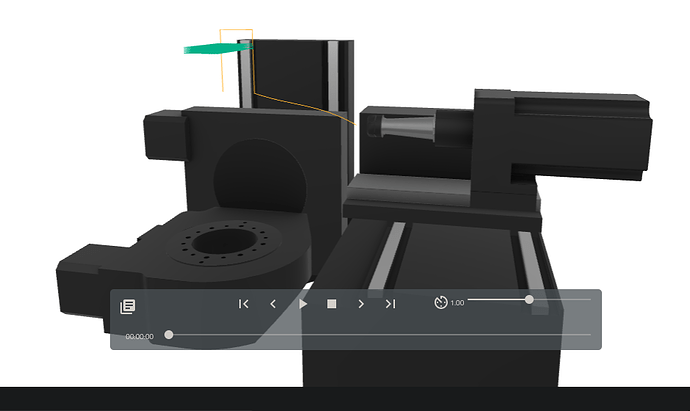

Consider when A = 0° & B = 0°, we set a WCS offset as Z=+0.2mm (ie to the right when looking at the main table). Now consider a tool path that simply requires A to be 90° - this ‘right direction’ is now straight down, ie Y=-0.2mm.

To reiterate, I would go into the Penta interface and set my WCS offsets in there. I leave G54 as all zeros since multiple users use the Pocket NC and most software defaults to use G54. But we have a custom plate which bolts to the B table with a pattern of dowel pin holes and after many, many careful measurements, it turns out that this plate has a rotational offset of 0.12° clockwise that cannot be corrected by loosening the screws and rotating etc and there’s some small X & Z offsets too. So under G55, we currently have X=0.05, Z=-0.15, B=0.12°. However when I made the measurements, A was set to 90° so my measurements were actually in X & Y. The X offset stays as is (so long as B = 0°), but +Y becomes -Z. Hopefully this helps get the penny to drop for you. Cut out a small arrow and a big arrow out of paper and use bluetac to stick these to the table pointing up/down and left/right. Then in the Midi, type G0 A90, and then G0 B90, and see what directions the arrows end up pointing.

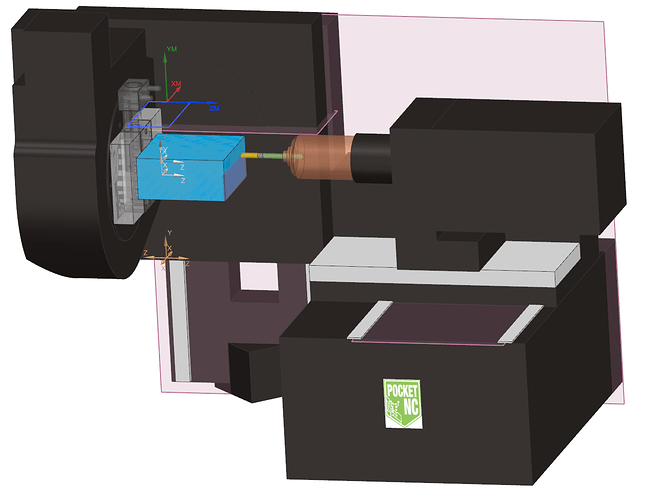

One thing thats worth mentioning is that in Fusion 360, all our Setups have the origin as the true origin of the machine (where the A table axis crossed in space with the B table axis) and so we just position parts in the software where they are on the machine. So our WCS offsets are all just small tweaks.