I’ve suddenly run into an error when trying to mill an item I’ve milled previously. I got the error message that joint 1 exceeds its negative limit, so I ran the Kinetic Simulator and sure enough, Y has continued up, off of the machine into the red zone. If I run the exact same G-Code through the Penta online simulator, everything looks good. Fusion’s simulator is good also. This leads me to believe the problem is within Kinetic control.

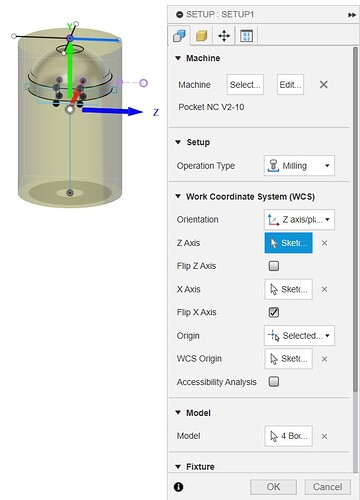

I’ve tried different WCS Origins, thinking the part or stock was incorrectly located.

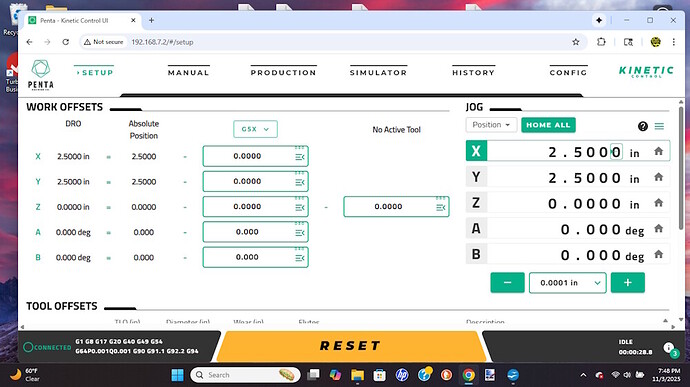

Any ideas I can look at? When ‘homed’ X and Y are both at 2.50.

This is on a V2-10 with the latest software version 5.8.4.

Are you able to post the gcode? Say the first 20 lines then the code that over travels with the proceeding 5 and trailing 5 lines ?

Also a screen shot of your setup screen that show origins etc. and include the bottom of the UI showing the active G and M codes.

Regards

TP

As soon as I hit the send button it dawned on my that the gcode would be a good thing to include.

Here are the first few lines of code. It bombs at line 19.

%

(AXIS,stop)

(SCRUBBER PART 1 V4)

G20

G90 G94 G40 G17 G91.1

G53 G0 Z0.

(ADAPTIVE6)

M0

(MANUAL TOOL CHANGE TO T19)

S9000 M3

G17 G90 G94

G54 G0

G53 G0 X2.5 Y2.5

G0 A90. B-180.

M254 P9

G59.3 G0

G43 H19

G1 X-0.5123 Y-0.3356 F500.

Z1.2132

G1 Z0.8132

Z0.6794

Z0.6669 F5.

The initial approach move to Z1.2132 likely exceeds the effective Y-axis travel after the kinematic transformation due to rotated work offsets. Can you reduce the z clearance a little just to test through the simulator?

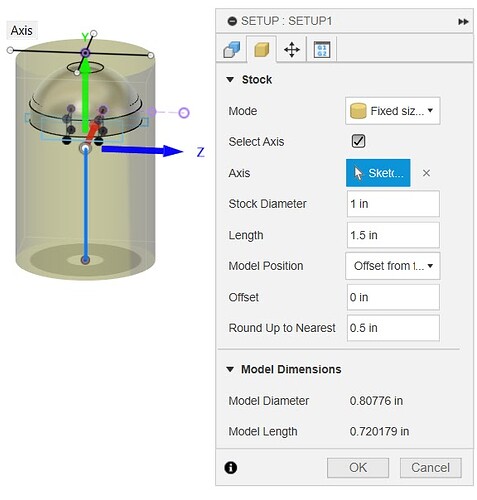

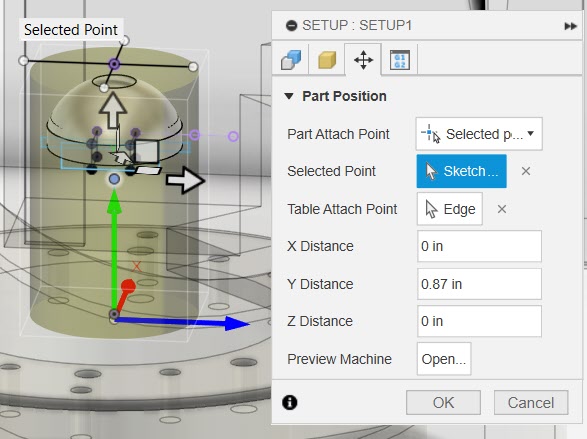

I compared my current setup with a previous file setup and noticed a difference in Setup/Part Position Y Distance value. I also noticed my current stock is shown off of the B Table. I changed the Y Distance value and it decreased the Z number you referenced .05". The simulator still shows Y running off of the machine. What I don’t understand, when running a previous gcode file that worked, now it has Y either running extreme + or -. I just ran the files without changing tools or their offsets, which I would expect a tool length error on Z, but it shouldn’t have Y climbing off of the machine. What else can I check for or change?

My machine wouldn’t take an online software upgrade, so I flashed an update that was sent to me. What if I go back to my previous software version and see if this still happens?

Working with round stock, I didn’t use TCPC, but I think I’ll try a new file with TCPC tomorrow.

Thanks for your help.

What is in your G54 work offset?

Work offset is -3.1624 for the g-code I provided above initially.

In Y? That seems like your problem. Try setting that to 0.

Maybe I misunderstood you. I thought you wanted the first tool offset. If it’s Y, it’s homed at -2.5 with no additional offset.

Can you show a screenshot of your Setup tab? I’m guessing you have a value in your Z work offset (rather than your tool offset). Your program is using G54 and at A90 B-180, a Z offset would translate to a Y movement like you described.

Click on the G5x menu and change it to anything except G54, then switch it back to G54. Then post that screenshot (this will ensure the data for G54 is active and showing).

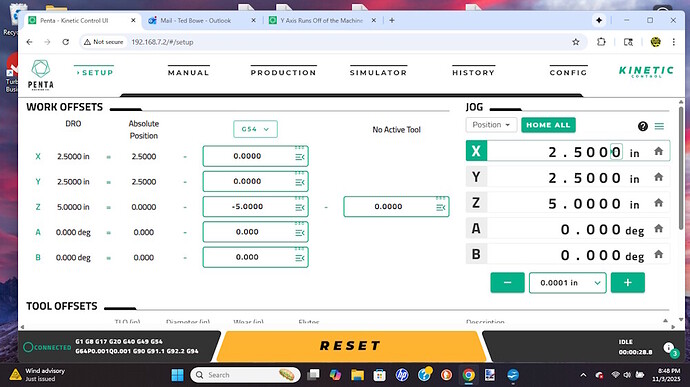

The Z value of your work offset should be zero. By setting it to -5, you’re telling kinetic control that your part is located 5 inches beyond the center of the B axis along the Z axis. When the A axis is rotated to 90 and B to -180, it’s going to attempt to make a Y move to get to that position, which it is unable to do.

Your tool length should be assigned to tool 19. What do you have in tool 19?

I’ve been meaning to post a question here regarding the Z axis. When initially homing after a boot, X and Y are 2.50 and Z, A and B are 0.00. If I home after the initial, Z varies around 2.xx. The only way to get it back to 0.00 is to shut down completely and restart. It’s been a real pain and it has done this since day 1. The -5.00 appeared after your suggestion of resetting G54. It isn’t something I entered. I tried a ‘home’ and Z remains at 5.00.

Z was at 0.00 when running my file. That’s why I have to restart to get it to 0.00. It only went to 5.00 after the G54 reset, which I just tried again (and a ‘home’) and Z hasn’t changed. I have to shut it down.

The #19 tool offset is -3.1624.

Restarting won’t clear the value. At startup it won’t show it properly until you run a program or click through the menu like I explained. To set it, click in the field and type 0 and hit enter.

I am now milling as we speak. Thank you for your time and support, which has always been fantastic.

Why all of a sudden did this runaway Y axis appear when all of this time it hasn’t been an issue. Nothing has changed and even previous files wouldn’t run.

And why doesn’t ‘home’ take Z to 0.00? Do I have to always set it to 0 manually?

Thanks again.

That -5 was specifically set by something. It sounds like it was accidental. Your work offset is a value that shifts the origin of the machine. The home position is always the same physical position, but when a work offset is in place it will show you position relative to that work offset. This allows you to have the same program work, even if you mount your part in a different physical location. You just need to take care to properly input that location into your work offset. If you’re not using that functionality you need to ensure your work offsets are zero. It will persist now that you’ve set it to 0. It’s a good practice to check those values before running a program, though.