When it comes to calculating speeds and feeds for various tools and materials most calculators require the max rpm, max cutting force, max torque and power of these PNC machines to get ballpark output data…can any here tell me this for the V2-50 so i can feed it into HSM advisor…thanks

I don’t lnow if its the same motor/drive as the one in the V2-50, but this document has a torque curve:

Cheers Mike ill take a look…

Out of curiosity im trying to machine hardened steel. the PNC is capable to machine steels up to 35HRC. Can anyone show me an example of the tooling they used and some successful speeds and feeds they have used to cut steel with…thanks

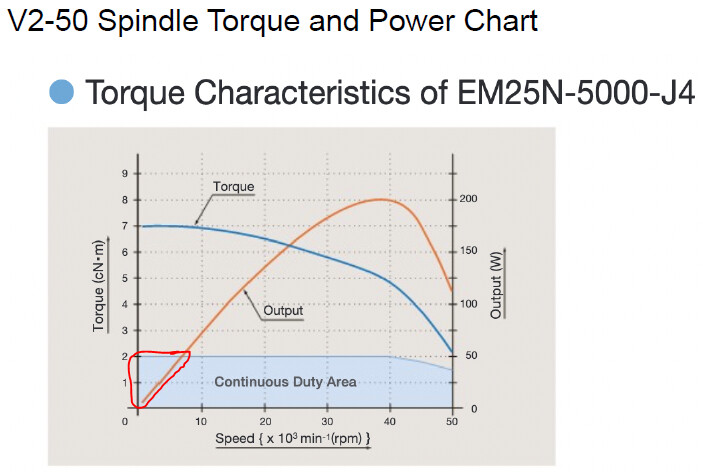

I have some data that I would like to share. I have attached a pdf document that includes the Nakanishi torque and power curve for the spindle motor on the Pocket NC V2-50. There has been some confusion regarding the interpretation of this curve. When making a cut, your spindle motor will be in the Continuous Duty Area of the curve, limiting the maximum continuous torque to 2 cN·m and maximum continuous power to 50 Watts. Above 40,000 rpm, the maximum torque and power are somewhat degraded. In the document, you will find some measurements of maximum cutting force that were obtained from the Y axis movement (which is inherently the most limited axis since it has to raise the mass of the trunnion and stock). You will notice that the maximum cutting force diminishes as the feed rate increases. These measurements values were determined just before motor stall occurs. I hope you find this helpful.

Pocket NC V2-50 Feeds and Speeds Calculator Data.pdf (394.7 KB)

Do you have a similar data sheet for V2-10? I’m trying to figure out what the max feed rate for my V2-10 is…should this just be based on each of the joint’s max velocities? Are those max velocities (e.g. z-axis max is 60 in/min listed here) assuming no load?

The maximum feed rate for the Pocket NC is 60 in/min (1524 mm/min). Our V2-10 speeds and feeds table on the User Resources page can be found here. These are just good starting values. Some experimentation with the feed and speed sliders on the user interface often results in good feeds and speeds values.

@MikeH - I’d like to point that the continuous power available below ~6500 RPM diminishes towards zero as the RPM tends to zero:

So you may wish to update the PDF at some point and remove that little triangle of blue.

And for anyone that’s interested, my V2-50 seems to be able to sustain spindle cutting powers of at least 75W for prolonged periods, so the plot that I’m currently working to is 0W at 0 RPM up to 75W at 10,000 RPM, and then flat 75W onwards. Note that my power measurements have been taking using a Smart Plug and to work out the spindle cutting power specifically I subtract a baseline power (0 RPM, with no axes moving) of around 32W, then I subtract the spindle idle power (ie no cutting) for a given RPM and the power specific to a particular axis feed rate, all of which can be combined into a single subtraction by making the same power measurement, making the same cut, but in thin air. Hopefully that makes sense. But don’t push the 50W (or 75W) unless you’re prepared for a stall!

@fnhalluk - I’m not affiliated with NSX; just found that chart on-line and thought it might be of interest to PNC owners here.

So sorry MikeH, I got the wrong PDF/link. I was meant to have aimed my post at @chuckknighton. Please accept my apologies.

No worries! Just didn’t to imply that I was with Penta/PNC.