When machining cylinders using the collet fixturing, what is the best way to find zero on the stock?

The main question is, do I first rotate my A axis by 90 degrees, find the 0-0 for x and y, touch the tool to the end of my part, then set all axes to be zero, and then machine? (I would have the stock 0-0 have the z-axis facing normal to the top surface of the cylinder.)

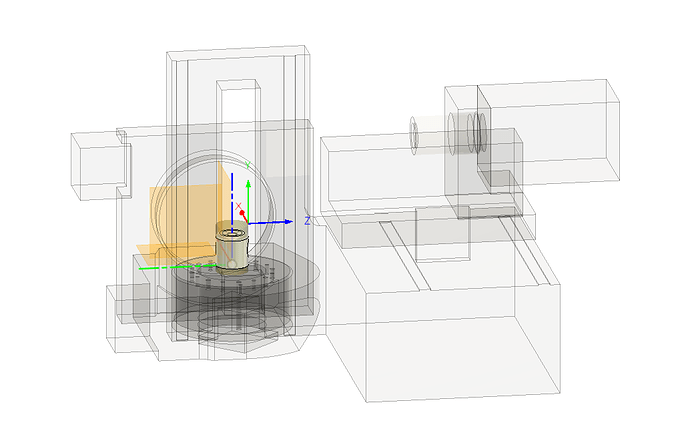

Or is it better to do how I have it set up like this and touch off to the side of the part?

My setup is like this.

Is there any sort of good guide for cylindrical parts? I completed the first part cube, but am looking for specifically a comprehensive guide for cylinders